Compared to recycling, it is much harder to make a profit when integrating repair in a business model. But it is possible, says Steve Kennedy, who researches systems and resilience thinking at the Rotterdam School of Management.‘The Right to Repair proposal is a step in the right direction, but we’re not there yet.’ By Hans Wetzels

The proposal on repair legislation that the EU adopted in March 2023 asks a couple of things of companies. They must try to encourage standardization of spare parts, or provide open access as to how a product is made, thereby ensuring that independent shops can repair it. It also makes it obligatory for companies to repair their own products, but only within the legal warranty period and only if proven to be a cheaper option than having it replaced by a new one.

Linear business models

Kennedy: ‘It means that companies can keep operating their own linear business models – in which more sales equals higher profits – and leave repair to independents if they fear that repair would reduce sales’, says Steve Kennedy, Associate Professor at the Rotterdam School of Management.’

Companies still want to believe in infinite growth of throughput on a finite planet.’

The company perspective

Kennedy researches how systems and resilience thinking can help organizations innovate to cope with challenges such as climate change or the loss of biodiversity. But Kennedy is sceptical when it comes to the willingness of businesses to facilitate innovative strategies such as repair. ‘In the end, they can continue to believe in infinite growth of throughput on a finite planet’, he says. ‘It will be a struggle to have them adopt repair as the business case often doesn’t look too good when a company is operating a standard linear business model.

Labor costs

The repair process itself may be difficult, complex, and costly, especially if the products are not designed to be easy to disassemble and repair. According to Kennedy, this often makes labour costs for repair a key stumbling block. ‘Companies may look into repair and find that the numbers don’t add up. And even if repair can be proven to be viable by means of fundamentally redesigned business models, companies may be unwilling to adopt these when current ones are not perceived as being flawed.’

Stimulating repair by shifting the tax burden

Stimulating repair by shifting the tax burden

The second Integral Circular Economic Report (ICER), as authored by the Dutch Planbureau voor de Leefomgeving (PBL), explicitly calls for the Dutch government to speed up the integration of repair to move its lagging transition to a circular economy forward. Kennedy looks at the past to understand how deeply rooted the problem is. ‘There used to be many repair shops for household appliances in every town’s main shopping street. But that was before the global economy emerged. Thanks to cheap globalized labour forces and advances in mass production, it now often is much cheaper to produce and buy a new product than to repair an old one.’

Repair can be stimulated by increasing taxes on materials and reducing taxes on labour.’

Potential business opportunities for repair

The share of economic activity from manufacturing in the EU has significantly declined, thanks to capitalist globalization and a growth in service industries. This has also impacted repair opportunities. ‘Large numbers of products available on the EU market are produced elsewhere. Are we to send all defective products back to Asia for repair? Or should companies set up repair services close to their EU-customers? The first option would make no sense because of the environmental footprint, the cost and time involved. The latter means that firms must build completely new teams for repair within Europe. This can be costly with only limited certainty that it will be worth the investment. And with labour heavily taxed, local repair in Europe can be expensive. Taxing materials more and labour less will help shift the balance between product replacement and product repair.’

Nevertheless, Kennedy feels that new business models incorporating repair services are viable. It will, however, require more progressive circular thinking by companies. ‘Offering a high-quality repair service can be part of a strong value proposition to the customer.

Fairphone

Take the Fairphone, for example, which has been specifically designed to be easily repaired by customers themselves, assisted by manuals and support. Customers may value this ease of repair or the reduced environmental impact, helping to set the company apart from its competitors.’

By retaining ownership, companies are incentivised to make the product as durable and easy to repair as possible.'

Selling access to a product instead of transferring ownership is another approach that can make repair services more viable. By retaining ownership, companies are incentivised to make the product as durable and easy to repair as possible. There are various examples, such as the leasing of bikes and even elevators. ‘Companies that innovate their business models with circularity in mind can still make healthy profits with repair included. A body of success cases and further education on the circular economy will accelerate the adoption of repair. So will consumers who demand easy repair and the implementation of stronger repair policies.’

Steve Kennedy is an associate professor at the Rotterdam School of Management. He researches how systems and resilience thinking can help organizations innovate to address climate change or biodiversity loss. Kennedy has been involved with Leiden-Delft-Erasmus Centre for Sustainability since its inception.

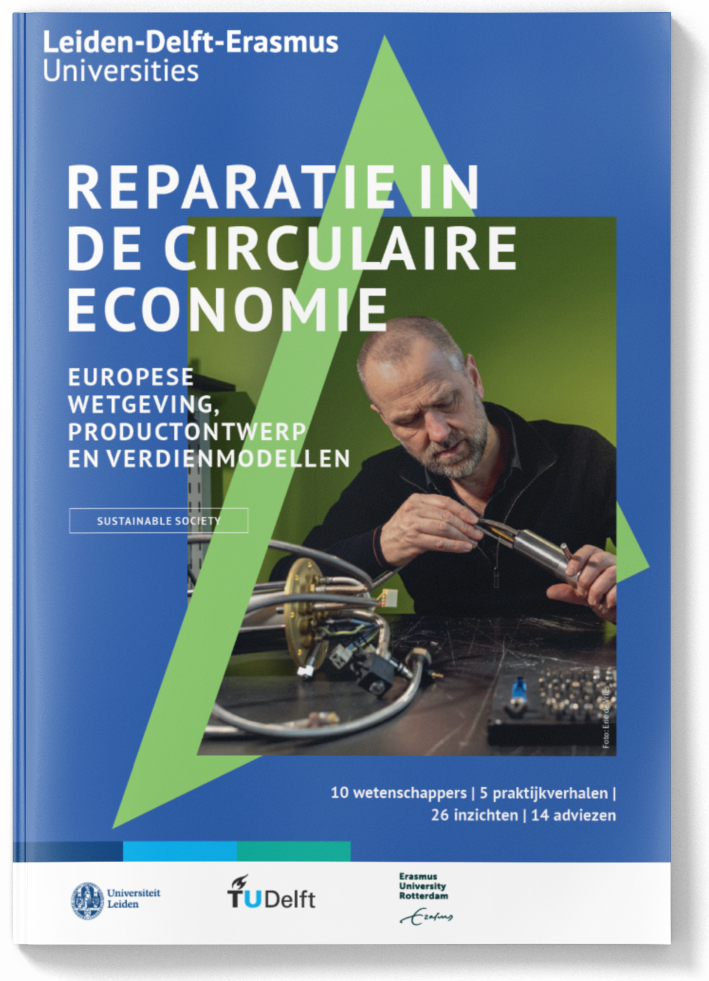

This is an article from the white paper 'Repair in the Circular Economy: European legislation, product design and business models'. Download the paper using the link below or order a printed copy using this form. The paper is also available in Dutch.

This is an article from the white paper 'Repair in the Circular Economy: European legislation, product design and business models'. Download the paper using the link below or order a printed copy using this form. The paper is also available in Dutch.